Grand-Hope New Materials – Defining New Standards for Third-Generation Semiconductor Thermal Fields with Nanoscale Carbon Architecture!

Amid the global wave of new materials industry upgrading, short-fiber hard felt—an indispensable core insulation material in high-end manufacturing sectors such as semiconductors and new energy photovoltaics—sees its technological breakthroughs and performance enhancements directly impacting the industry’s independent control, cost reduction, and efficiency improvement.

Building on advanced international foundations, Grand-Hope New Materials has deepened its expertise through comprehensive technological iteration and innovation, launching short-fiber hard felt insulation materials with superior performance, optimized costs, and broader applications. This has positioned the company as a core driving force in industry advancement.

Technological Core Upgrade: From "Independent Control" to "Global Leadership"

Grand-Hope New Materials recognizes core technology as the foundation of enterprise success. Collaborating with specialized materials research institutes, the company formed a dedicated R&D team and spent three years completing technological iteration.

Compared to traditional processes, Grand-Hope’s independently developed "Supercritical Fluid-Assisted Molding Technology" achieves three breakthroughs:

First, it overcomes the challenge of uniform short-fiber dispersion. By precisely controlling fluid pressure and flow rate, the distribution error of short carbon fibers during molding is reduced to less than 3%, significantly enhancing thermal field stability.

Second, it innovates a composite binding system. Using a self-developed binder, it avoids the decomposition and failure of traditional binders under high temperatures, improving overall material structural integrity by 40%.

Third, it achieves full-process intelligent equipment. Equipped with an AI temperature control system and an online quality monitoring module, production efficiency is increased by 50% compared to industry standards, with product qualification rates consistently exceeding 99.8%.

Grand-Hope has completely shattered the stereotype that "domestication equals technological catch-up," positioning its technical capabilities among the global first tier.

Performance Parameter Leap: Pushing the Limits of High-Temperature Insulation Materials

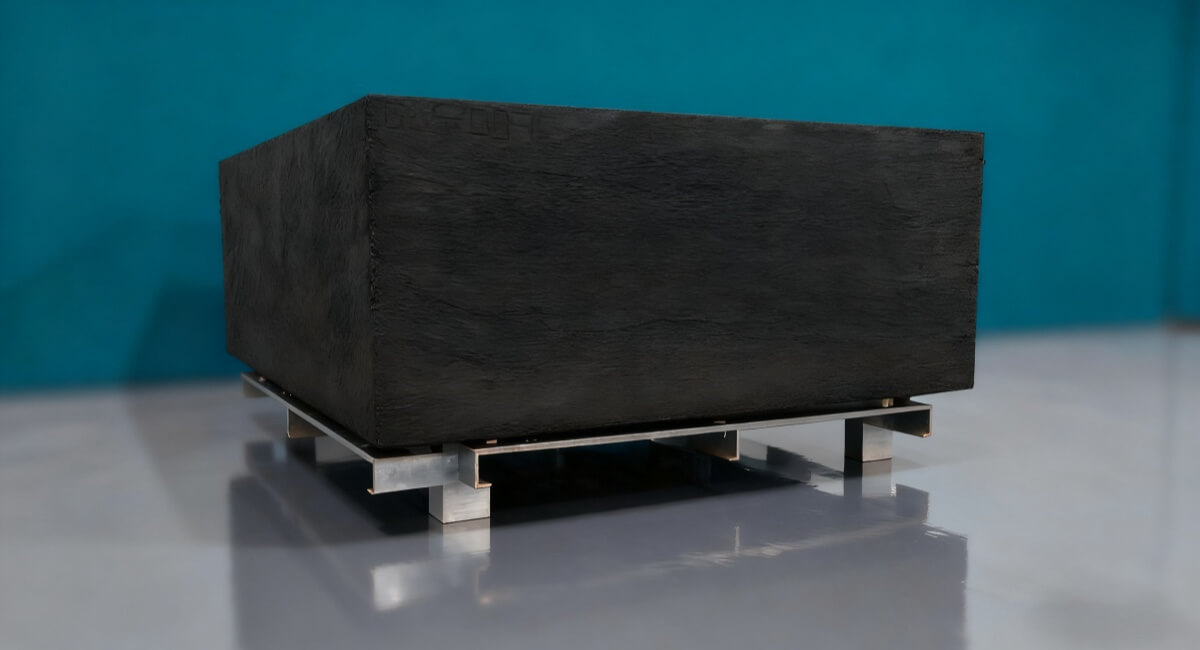

Under stringent demands for insulation materials in high-end manufacturing, Grand-Hope’s short-fiber hard felt achieves comprehensive performance superiority with three core advantages: ultra-high temperature resistance, ultra-low thermal conductivity, and ultra-high stability.

Addressing the pain points of traditional materials—such as thermal field drift, susceptibility to corrosion, and short lifespan—Grand-Hope enhances corrosion resistance severalfold through fiber surface modification. Additionally, product density can be precisely adjusted between 0.16–0.18 g/cm³ to balance insulation effectiveness and structural strength, meeting customized requirements for various high-temperature furnaces.

Dual Advantages of Cost and Environmental Friendliness: Empowering Industrial Cost Reduction and Efficiency Improvement

The core value of breaking foreign monopolies lies in "independent cost advantages." Grand-Hope has achieved a dual breakthrough of "cost optimization + environmental upgrade" on this foundation. By establishing a closed-loop industrial chain of "short-fiber recycling, modification, molding, and reuse," the company elevates the utilization rate of short carbon fiber scraps to 99%, an 18-percentage-point increase over the industry average.

Simultaneously, intelligent production equipment reduces unit energy consumption by 28%, achieves zero wastewater discharge during production, and cuts carbon emissions by 40% compared to traditional processes, fully aligning with the "Dual Carbon" strategic requirements.

In terms of cost, through process optimization and economies of scale, Grand-Hope reduces the unit production cost of short-fiber hard felt by an additional 25% compared to industry standards. The market price is only one-fifth of imported products and 15%–20% lower than domestic counterparts.

Application Scenario Expansion: From Core Sectors to Diverse Empowerment

Leveraging outstanding comprehensive performance, Grand-Hope’s short-fiber hard felt has expanded from core sectors like semiconductors and new energy photovoltaics to high-end applications such as aerospace high-temperature components, metallurgical specialty furnaces, and nuclear industry insulation and protection. In tests conducted by a leading photovoltaic enterprise, high-temperature furnaces using Grand-Hope’s short-fiber hard felt reduced single-furnace production cycles by 8% and decreased equipment maintenance frequency.

In the aerospace sector, its lightweight and high-temperature resistance properties have been successfully applied to the development of prototype components for spacecraft thermal protection systems.

A Grand-Hope New Materials representative stated, "The domestication of short-fiber hard felt is not the end goal but the starting point for Chinese new materials to go global." Moving forward, Grand-Hope will continue to focus on technological innovation in high-temperature insulation materials, with plans to launch next-generation products capable of withstanding 3500°C and expand into overseas markets, positioning China’s independently developed high-end new materials at the core of the global industrial chain.

From technological breakthroughs to industrial empowerment, Grand-Hope New Materials, with its short-fiber hard felt insulation materials offering "higher performance, lower costs, and superior environmental friendliness," has not only reshaped the competitive landscape of domestic high-temperature insulation materials but also provided a vivid example of China’s new materials industry transitioning from "following" to "leading." In the wave of global high-end manufacturing industry upgrades, Grand-Hope is writing a new chapter in China’s independent control of new materials, using technological innovation as the pen and industrial responsibility as the ink.