High-Performance Carbon Fiber Insulation Materials in the Fiber Optics Industry

High-performance carbon fiber insulation materials combine the advantages of carbon fiber, such as high strength, low thermal expansion coefficient, high thermal conductivity, and the design flexibility of composite materials, while also offering excellent thermal insulation properties. These characteristics enable them to address the limitations of traditional materials in critical stages of fiber optic technology.

Advantages:

Extremely low thermal expansion coefficient: Highly compatible with the CTE of quartz glass fiber, preventing stress caused by temperature changes that could affect fiber performance.

High strength-to-weight ratio/high modulus: Extremely robust yet lightweight, ideal for weight-sensitive, demanding environments.

Excellent thermal stability and heat resistance: Capable of long-term operation in high-temperature environments without performance degradation.

Customizable anisotropic thermal conductivity/insulation properties: Enables efficient heat conduction (cooling) in one direction and extreme thermal insulation (heating) in another direction.

Corrosion-resistant and fatigue-resistant: Suitable for complex chemical environments and high-vibration scenarios.

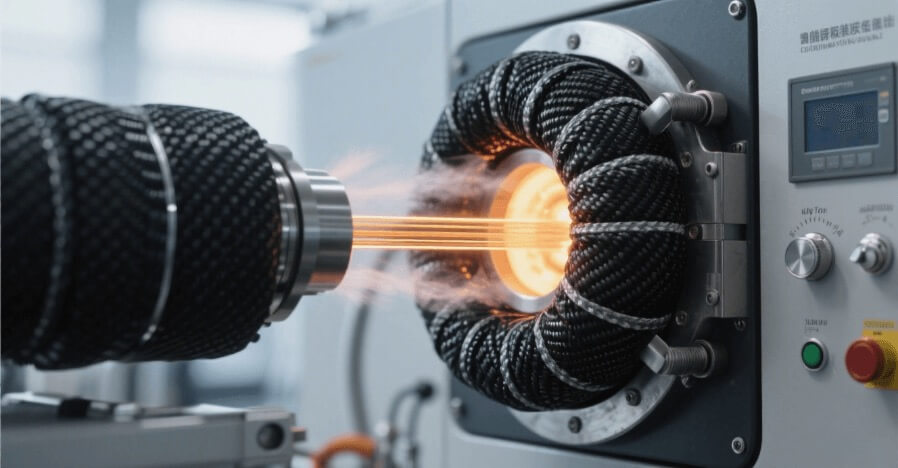

High-precision insulation body for optical fiber drawing towers

In the process of drawing optical fiber preforms into optical fibers, the drawing furnace is a critical piece of equipment. The furnace temperature exceeds 2000°C, requiring an extremely stable and uniform thermal field to ensure uniform fiber diameter (even micron-level fluctuations can cause signal attenuation).

Traditional Materials | Carbon fiber composite insulation materials |

|---|---|

Heavy graphite materials are extensively used as heating elements and insulation screens. Graphite is brittle, prone to cracking, and undergoes continuous oxidation and degradation at high temperatures, necessitating regular replacement and resulting in high maintenance costs. | 1. Used as the insulation layer in drawing furnaces. Its extremely low thermal conductivity effectively reduces heat loss, significantly lowering energy consumption. 2. Utilizing its high strength and low thermal expansion, it is fabricated into support structural components for furnace chambers. It can withstand high temperatures, and its CTE matches that of internal graphite components, ensuring consistent deformation during temperature changes. This maintains the long-term structural stability and geometric accuracy of the thermal field, directly improving fiber drawing quality and consistency. 3. Energy saving, reduced consumption, improved fiber quality, and extended equipment maintenance cycles |

The “protective housing” for aerospace fiber optic sensing systems

Aircraft, satellites, and other aerospace vehicles extensively use fiber Bragg grating (FBG) sensors to monitor strain, temperature, and vibration in critical areas such as wings and fuselages in real time. These sensor systems are highly sensitive to temperature and mechanical vibrations.

Traditional materials | Carbon fiber composite insulation materials |

|---|---|

Sensors are typically exposed or protected by simple rubber/metal sheaths, which struggle to withstand extreme temperature fluctuations and severe mechanical vibrations | 1. This material is used to create a miniature "protective housing" for FBG sensors. Its low coefficient of thermal expansion (CTE) ensures that the housing does not exert compressive or tensile stress on the internal fiber due to temperature changes, thereby preventing measurement errors. 2. Excellent thermal insulation Protects sensors from sudden external high or low temperatures (e.g., atmospheric reentry, changes in sunlight exposure), ensuring accurate temperature readings. Additionally, the composite material's high damping properties absorb and isolate external mechanical vibrations, preventing vibration noise from interfering with strain signal measurements. 3. Enhances the accuracy and reliability of sensor data, protects precision sensors, and adapts to extreme temperature variation environments. |

The “Thermal Management Guardian” for High-Power Fiber Lasers

The laser gain fibers in high-power fiber lasers generate a significant amount of waste heat during operation. If this heat is not promptly and directionally dissipated, it can cause temperature increases,leading to thermal lensing effects, mode instability, or even fiber damage.

Traditional materials | Carbon fiber composite insulation materials |

|---|---|

Typically, metal water-cooled heat sinks are used, but metals have isotropic thermal conductivity, which may direct heat toward undesirable directions. | 1. Utilize their designable anisotropic thermal conductivity to manufacture specialized heat dissipation components. For example, make them highly thermally conductive perpendicular to the fiber direction to quickly direct heat generated by the fiber toward the water-cooled plate; while maintaining thermal insulation parallel to the fiber direction to prevent heat from propagating along the fiber and affecting other temperature-sensitive components (such as Bragg gratings). 2. Replace part of the metal structure to reduce the overall weight of the laser system, which is particularly important for mobile platforms (e.g., vehicle-mounted or airborne lasers). 3. Efficient directional thermal management, enhancing laser output power and beam quality, and lightweight design. |

High-performance carbon fiber composite insulation materials, with their unique comprehensive properties, have found indispensable high-value applications in the fiber optic field from the manufacturing end (drawing towers) to the application end (optical cables, sensors, lasers), making them one of the key advanced materials driving the development of fiber optic technology toward higher performance, greater reliability, and energy efficiency.