High-performance carbon fiber insulation materials in the field of sapphire growth

Sapphire (α-Al₂O₃ single crystal) has a melting point as high as 2054°C, and its growth process demands the utmost stability, uniformity, and thermal insulation of the thermal field, as these factors directly determine the quality, size, and economic viability of the crystal production. High-performance carbon fiber composite insulation materials, with their unique comprehensive properties, are playing a revolutionary role in this field.

KY Method's "All-Around Thermal Insulation Fortress"

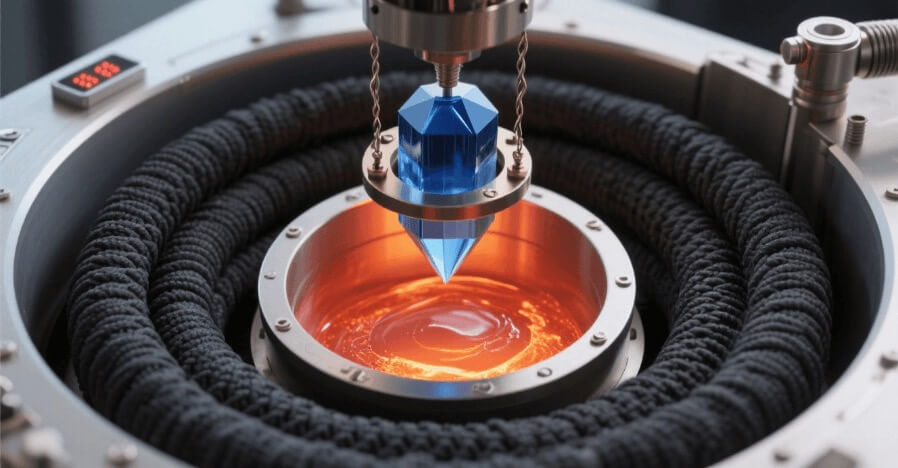

In the KY method, raw materials are melted in tungsten or molybdenum crucibles, and seed crystals are immersed before crystal growth is achieved through precise temperature control. The entire system must be enclosed by a robust insulation system (thermal field) to maintain ultra-high temperatures and establish strict radial and axial temperature gradients.

Traditional materials | Carbon fiber composite insulation materials |

|---|---|

Insulation layers are constructed using multiple layers of graphite felt, which are heavy, prone to damage, and exhibit a significant decline in insulation performance with increased usage. | Insulation cylinders, lids, and bases made from carbon fiber composite materials fully enclose the crucible, forming a robust "insulation fortress." |

Value delivered by high-performance carbon fiber insulation materials:

Ultimate energy efficiency: Its extremely low radial thermal conductivity effectively "traps" heat, saving a significant amount of electricity used to maintain temperatures of 2050°C (energy savings of up to 25% or more), directly reducing production costs.

Exceptional stability: The material's outstanding thermal shock resistance and structural stability enable it to withstand countless thermal cycles from room temperature to over 2000°C without cracking or collapsing. This ensures the thermal field's geometric shape remains unchanged over time, providing an extremely stable growth environment—the most critical prerequisite for producing low-stress, crack-free, high-quality large sapphire crystals.

High Purity and Long Lifespan: The significantly lower volatility compared to graphite results in minimal carbon contamination, yielding sapphire crystals with high purity and excellent optical properties. Additionally, its ultra-long lifespan extends the replacement cycle of thermal field components from several months with traditional materials to one or two years, significantly reducing downtime and maintenance costs

EFG Method's "Precision Boundary Controller" for Edge Thermal Fields

Precise thermal field control: Acts as a "thermal boundary controller," effectively eliminating edge effects and forming nearly ideal vertical temperature gradients at the growth interface, ensuring that the crystal grows uniformly and stably upward.

Traditional materials | Carbon fiber composite insulation materials |

|---|---|

Graphite felt insulation screens struggle to precisely control heat flow, often leading to rapid heat dissipation at crystal edges, resulting in internal stress, uneven thickness, or even cracking. | Special insulation screens made from this material are installed on both sides of the growing crystal sheet. They can be designed to provide extreme thermal insulation perpendicular to the crystal sheet, preventing heat loss to the furnace wall, while maintaining a certain thermal conductivity parallel to the crystal sheet to balance temperatures between the edges and center. |

The value of high-performance carbon fiber insulation materials:

Improved yield and quality: Significantly improves the thickness uniformity of the wafer and reduces internal stress, which means that the yield of subsequent processing (such as LED substrate processing) is fundamentally improved, and the optical aberration of the produced window plates is reduced.

In the ultra-high-temperature, long-cycle, and extremely quality-demanding field of sapphire growth, high-performance carbon fiber composite insulation materials are not merely an upgrade or replacement but a key enabling technology driving the industry toward larger sizes, lower costs, and higher yield rates. They comprehensively enhance the technical level and economic viability of sapphire crystal growth from four dimensions: energy efficiency, stability, purity, and safety.