Selection of Application Cases for Short Fiber Rigid Felt Insulation Material

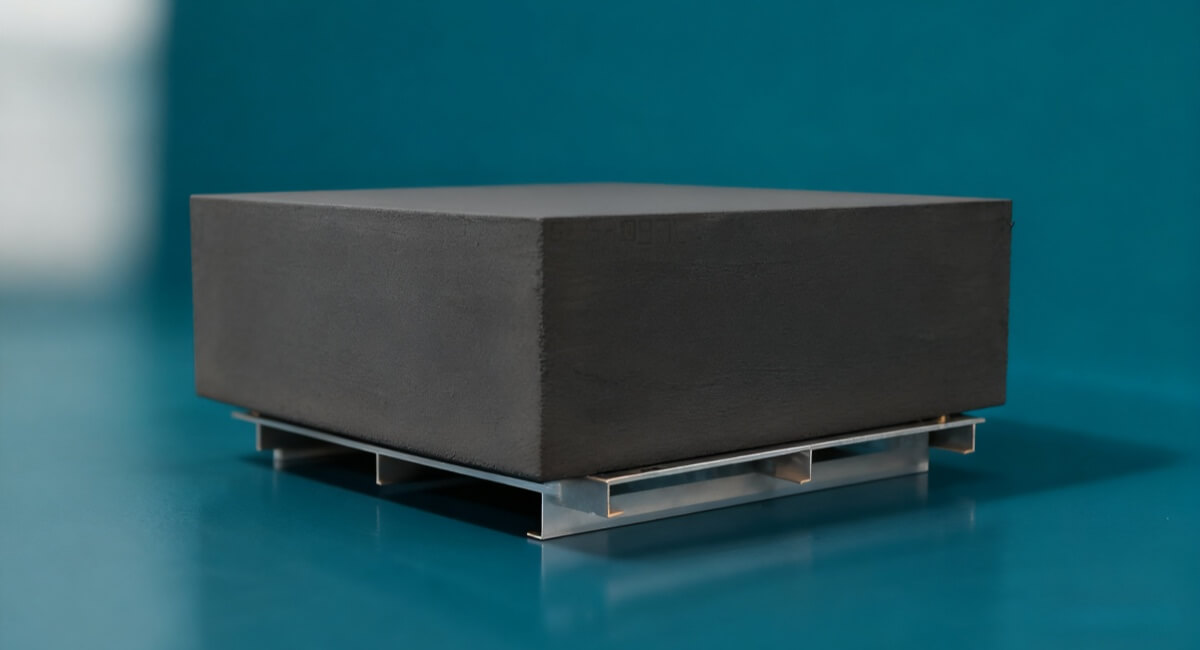

Short fiber rigid felt insulation material is a high-performance insulating material primarily made from short carbon fibers, manufactured through processes such as wet forming and hot pressing. It boasts core advantages including high-temperature resistance (above 3000°C), low thermal conductivity, high strength, and excellent thermal stability. It has already achieved groundbreaking applications in multiple high-end manufacturing sectors.

I. Semiconductor Industry: Guardian of the Thermal Field's "Heart"

1. Application in Monocrystalline Silicon Growth Furnaces

- Furnace Bottom Insulation System: Short fiber rigid felt replaces traditional graphite materials, reducing thermal conductivity to ≤0.038 W/(m·K), cutting heat loss by 22%, lowering single-furnace energy consumption by 15-20%, and reducing production cost per ton of silicon by 12,000 RMB.

- Insulation Cylinders and Guide Tubes: Hunan Shuanghuan's rigid felt products, applied by a leading silicon materials enterprise, increased pull speed by 35%, improved crystal yield by 2-3%, and extended equipment lifespan by 40%.

2. Silicon Carbide (SiC) Substrate Growth

- PVT Growth Furnace Thermal Field: Guanhe New Materials' SiC rigid felt has passed verification by a leading domestic SiC customer and is supplied in bulk. Its insulation sleeves, upper/lower insulation disks, and partitions all use short fiber rigid felt, ensuring thermal field stability at 2300°C, improving crystal growth uniformity by 18%, and breaking the monopoly of American, French, and German manufacturers.

- Special Design: A manufacturer uses a patented radial low thermal conductivity insulation cylinder (≤0.12 W/(m·K)), particularly suitable for growing third-generation semiconductor materials like monocrystalline gallium oxide which have extremely high thermal field requirements.

II. Photovoltaic Industry: Efficient "Light" Catcher

1. Monocrystalline Silicon Pulling Furnaces

- Comprehensive Thermal Field Application: Short fiber rigid felt is used in key parts like furnace bottom, guide tubes, cover plates, and insulation cylinders, forming a "thermal field protective garment." This improves furnace temperature distribution uniformity by 25% and shortens silicon ingot growth cycle by 8%.

- Actual Case: Zhejiang Jingcheng signed a 45-million-RMB graphite rigid felt procurement order with Germany's SGL, proving the essential status of this material in high-end photovoltaic equipment.

2. Polysilicon Casting Furnaces

- Furnace Wall and Roof Insulation: Short fiber rigid felt replaces traditional ceramic fiber, improving high-temperature resistance by 30%, extending service life to 8000 hours (a 60% increase), reducing maintenance frequency by 50%, and generating annual comprehensive benefits exceeding ten million RMB.

III. Metallurgy & New Material Synthesis: "Voltage Stabilizer" for High-Temperature Processes

1. Hard Alloy Sintering Furnaces

- Furnace Chamber Insulation System: Using needled structure carbon fiber rigid felt for insulation cylinders and furnace lids maintains stability at 1600°C, controls furnace temperature uniformity error within ±2°C, improves product yield by 12%, and reduces energy consumption by 20%.

2. Vacuum Heat Treatment Furnaces

- Insulation Lining: The good electrical insulation and thermal stability of short fiber rigid felt make it particularly suitable for vacuum induction furnaces. After application by an automotive parts company, heat treatment deformation rate reduced by 40% and energy consumption dropped by 28%.

3. Powder Metallurgy Field

- Hot Isostatic Pressing (HIP) Furnaces: Insulation door panels made from integrally needled carbon fiber rigid felt withstand temperatures above 2000°C, ensuring thermal field stability under high pressure. After adoption by an aero-engine component manufacturer, product density consistency improved by 25%.

IV. Other Cutting-Edge Fields: Pioneer of Innovative Applications

1. Optical Fiber Manufacturing

- Preform Melting Furnaces: Short fiber rigid felt used for furnace wall insulation ensures temperature uniformity at 2200°C. After application by a leading optical fiber company, preform refractive index uniformity improved by 15% and fiber yield increased by 3%.

2. Aerospace

- Engine Component Insulation: Lightweight short fiber rigid felt used in prototype spacecraft thermal protection systems weighs only 1/3 of traditional metal materials, withstands temperatures up to 2500°C. Tests by a space research institute showed thermal protection efficiency improved by 50%.

3. Nuclear Industry

- High-Temperature Experimental Devices: Short fiber rigid felt serves as internal insulation components in nuclear reactors, tolerating combined strong radiation and high-temperature environments. After application by a research institute, equipment operational stability improved by 60% and maintenance cycles doubled.

V. Domestic Substitution: A Milestone in Breaking Monopolies

- Guanhe New Materials Short Fiber Rigid Felt Application Case: In the field of SiC substrate crystal growth, it has become one of the few domestic manufacturers to pass verification by leading SiC customers and supply in bulk. Its product performance matches international top-tier levels, yet costs 15-20% less, successfully replacing imports and safeguarding supply chain security.

- Second-Phase Capacity Expansion: A 150-million-RMB investment in a Henan base for a 500-ton annual production line will further expand market share in high-growth fields like semiconductor and photovoltaic thermal fields.

- Hunan Shuanghuan Short Fiber Rigid Felt Application Case: Its independently developed carbon fiber rigid felt wet forming equipment has been successfully delivered. The produced rigid felt is used by a leading silicon materials enterprise, achieving a "from 0 to 1" breakthrough in thermal field materials, offering better performance, lower cost, and higher environmental friendliness. — Hunan Provincial Department of Industry and Information Technology

VI. Short Fiber Rigid Felt Application Advantage Comparison

| Application Scenario | Traditional Material | Short Fiber Rigid Felt | Performance Improvement |

|---|---|---|---|

| Monocrystalline Silicon Furnace | Graphite / Ceramic Fiber | Short Fiber Rigid Felt | Thermal Conductivity ↓15%, Energy Consumption ↓20%, Lifespan ↑60% |

| Silicon Carbide Furnace | Imported Graphite Rigid Felt | Domestic Short Fiber Rigid Felt | Cost ↓15-20%, Thermal Field Stability ↑18% |

| Vacuum Furnace | General Insulation Material | Short Fiber Rigid Felt | Insulation ↑, Temperature Resistance ↑30%, Deformation Rate ↓40% |

| Powder Metallurgy | Traditional Insulation Bricks | Short Fiber Rigid Felt | Weight ↓50%, Uniformity ↑25%, Energy Consumption ↓28% |

Summary

Short fiber rigid felt insulation material, with its outstanding high-temperature resistance, low thermal conductivity, and thermal stability, has become an indispensable key material in high-end manufacturing industries like semiconductors, photovoltaics, and metallurgy. Especially under the wave of domestic substitution, Chinese companies represented by Guanhe New Materials and Hunan Shuanghuan are breaking foreign monopolies, providing "Chinese solutions" with better performance and more affordable prices.