Single Company Ships Over 10 Million SiC Units, SiC MOSFET Races Ahead in New Fast Lane.

As fast-charging technology rapidly evolves, silicon carbide (SiC) is penetrating the consumer electronics sector at an unprecedented pace. With the ongoing optimization of SiC MOSFET costs, their high cost-performance advantage is becoming increasingly prominent. This not only breaks through the previous limitations of high-voltage applications primarily in industrial and automotive fields but has also successfully opened the door to the consumer fast-charging market.

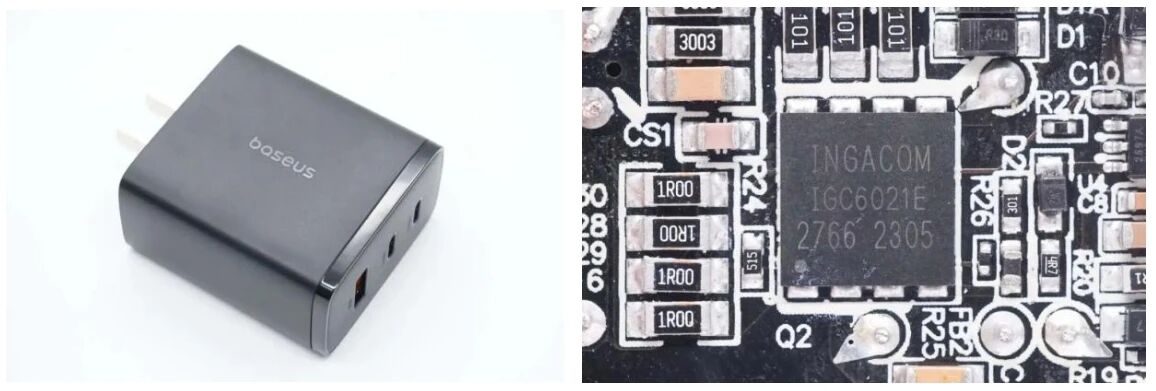

Currently, leading charging accessory brands such as Philips, Baseus, Ugreen, and Mains Power have successively adopted SiC MOSFET solutions, propelling PD fast-charging towards higher efficiency and smaller form factors. Research indicates that several SiC companies are focusing on the PD fast-charging segment, with some manufacturers' SiC MOSFET shipments expected to exceed 10 million units, highlighting the significant potential of this niche track.

In this wave, Injoinic Semiconductor, leveraging its comprehensive layout across both SiC and GaN technological paths, is emerging as a key player bridging technological upgrades and market applications.

Multiple PD Charger Manufacturers Adopt SiC, Injoinic SiC MOSFET Ships in Volume

According to incomplete statistics, over 30 PD fast-chargers have now incorporated SiC power devices. Top-tier smartphone fast-charging manufacturers like Philips, Baseus, Ugreen, and Mains Power have also integrated SiC into their solutions, quietly unlocking the massive potential of SiC in the consumer fast-charging market.

Amidst the tide of PD fast-charging technology upgrades, Injoinic's 750V SiC MOSFET products have won favor from several renowned PD charger manufacturers like Mains Power, Reijada, and LERUYI, thanks to their exceptional performance and reliability. These products have become key technological enablers for creating high-performance fast-charging products.

So, why are smartphone fast-charging manufacturers turning their attention to SiC MOSFETs? And why are they choosing Injoinic's SiC solutions?

An Injoinic representative emphasized, "In the current smartphone PD fast-charging market, SiC devices have become a crucial component for achieving high-efficiency, high-power-density charging solutions."

They further analyzed that SiC's rapid entry into this market is primarily driven by two practical factors: first, meeting PFC regulatory requirements for power supplies above 75W, and second, addressing the extreme pursuit of miniaturization in end devices. These two demands precisely highlight the multiple performance advantages inherent to SiC material itself.

1. High-Temperature Performance Advantage: SiC devices demonstrate stable performance in high-temperature environments, with on-resistance decreasing by up to 40% at 125°C. They also offer advantages in smaller size, performance, and cost. Based on this, some fast-charging manufacturers are transitioning from their original silicon-based MOS solutions, often using a factor of 1.4 as a reference when adopting Injoinic's 750V SiC solution.

2. Avalanche Breakdown Advantage: Compared to GaN, SiC MOSFETs possess avalanche capability. For example, the recent 65W SiC PD fast charger jointly launched by Injoinic and Mains Power utilizes Injoinic's 750V SiC device, achieving an avalanche breakdown voltage exceeding 850V, providing higher safety redundancy for consumer electronics applications.

3. Short-Circuit Withstand Advantage: Injoinic's 750V SiC MOSFETs are designed with a short-circuit withstand time of 2.5µs, balancing the device's high performance with safety requirements in practical applications.

4. Reliability Advantage: Due to their low lattice defect density, SiC MOSFETs offer reliability comparable to traditional VDMOS. They are not only suitable for consumer electronics but are also widely used in demanding fields like industrial control and automotive electronics.

5. No Dynamic ON-Resistance (Rds(on)) Degradation Advantage: Under high-voltage hard-switching and Continuous Conduction Mode (CCM), many power devices face the challenge of increasing dynamic resistance. SiC devices, however, are almost unaffected, ensuring more stable and reliable system operation.

6. Cost Advantage: The Injoinic representative noted that SiC device costs are continuously declining, with system costs in some applications already lower than those of silicon-based MOSFET solutions. Mass production on 8-inch wafers will further push SiC to break through its original application boundaries and accelerate its entry into the PD fast-charging and adapter markets.

The Injoinic representative stated that these advantages have been validated in practical applications. Their 65W PD fast-charging system, developed based on the 750V 360mΩ SiC device, not only exhibits clean switching waveforms and adjustable speed but also achieves a full-load low-temperature operation of 73°C under harsh 90VAC conditions, comprehensively demonstrating its exceptional efficiency and high-temperature stability.

Given these advantages, what market size will SiC MOSFETs unlock? Research suggests the annual demand for fast-charging adapters is estimated to reach 2-3 billion units in the future. This could potentially create a market worth tens of billions for SiC devices, with prospects looking even more promising in the high-power fast-charging segment.

Currently, Injoinic has made significant progress in the smartphone fast-charging field, but its vision is not limited to this. The company representative stated that Injoinic is actively introducing SiC MOSFETs into more consumer electronics scenarios such as TVs, adapters, LED drivers, and two-wheeler chargers, further expanding the boundaries of technology implementation.

Accordingly, Injoinic has formulated detailed plans: it will commence mass production of 750V 60-1200mΩ consumer-grade SiC products on 6-inch wafers in the fourth quarter of this year, followed by mass production of 750V and other products on 8-inch wafers. This aims to expand production scale, further enhance capacity and cost-control capabilities, and strengthen overall competitiveness in markets like consumer fast-charging and industrial power supplies.

Injoinic's SiC power devices now cover 750V-3300V, with resistance values ranging from 13mΩ to 55Ω. They have achieved volume shipments in consumer, industrial, and automotive-grade sectors, with shipment volumes ranking among the top in the industry.

Breakthroughs in Technology and Market, Injoinic GaN Adopted by Leading Clients

While continuously advancing in the SiC field, Injoinic has also observed that customer demands are becoming increasingly diversified as the PD fast-charging market matures. To comprehensively address this trend, Injoinic, drawing on its profound technological expertise, has also deployed mature and competitive Gallium Nitride (GaN) solutions in the PD fast-charging market. This caters to the needs of fast-charging products with varying application scenarios and performance requirements.

The Injoinic representative systematically outlined the technical layout and core advantages of its GaN solutions.

First, Injoinic has a comprehensive product line layout for GaN, including both D-GaN and E-GaN products, offering a complete portfolio. The representative pointed out that Injoinic's mainstream DFN and TO series comprise around 30 mass-produced specifications, with resistance covering 100mΩ to 600mΩ. This can fully match various PD fast-charging applications from 30W to 240W, meeting the demands of leading manufacturers and mainstream market applications. For instance, Baseus's 65W 2C1A GaN charger utilizes Injoinic's 650V/250mΩ GaN switch.

Focusing on core performance, Injoinic's GaN devices typically have a hard breakdown voltage exceeding 1000V, effectively resisting voltage spikes during operation. Simultaneously, their dynamic ON-resistance is less than 10%, placing these metrics at the forefront of the industry.

The Injoinic representative emphasized that Injoinic provides complete system-level solutions. Taking a 240W PFC+LLC architecture as an example, they can offer a complete solution consisting of high-performance GaN switches and optimized silicon nitride diodes. By systematically reducing losses and improving efficiency, they help customers create more competitive end products.

Notably, regarding product strategy, Injoinic has also established a clear technology roadmap.

For the E-GaN technology path, Injoinic's products cover 700V and 900V low-power co-packaged devices, medium/high-voltage bidirectional devices, and low-voltage (below 200V) and low-voltage symmetric (bidirectional) devices. Currently, high-voltage and low-voltage E-GaN devices are in full mass production on 6-inch wafer lines. Plans are in place to migrate to 8-inch production lines in Q2 2026, which will further enhance product cost competitiveness.

For the D-GaN technology path, Injoinic focuses on low-power high-voltage devices. 900V devices are already in mass production, and future plans include launching a series of low Rds(on) D-GaN products to meet more diverse application needs.

Today, with its complete product matrix, Injoinic's mass-produced GaN power device specifications exceed 30 models, covering both high-voltage and low-voltage series, with shipment volumes consistently ranking among the top domestic manufacturers.

Overall, through continuous dedication and innovation in both SiC and GaN tracks, Injoinic has formed a comprehensive and high-performance product portfolio. This enables the company to provide diverse, high-performance solutions for fast-charging customers, helping them gain a competitive edge in the fierce market.

It is foreseeable that as third-generation semiconductor technology continues to mature and costs optimize, SiC and GaN will form a complementary and co-evolving landscape in the fast-charging market. Leveraging its deep presence in both SiC and GaN fields, Injoinic will continue to provide customers with high-performance, high-reliability power solutions.

Looking ahead, Injoinic stated that the company will continue to increase R&D investment, deepen product innovation, assist fast-charging technology in advancing towards higher power, smaller size, and better user experience, and drive the entire industry forward continuously.